Plasma equipment sputtering target production line and milling system.

Spraying production line of target

Spraying target production line product

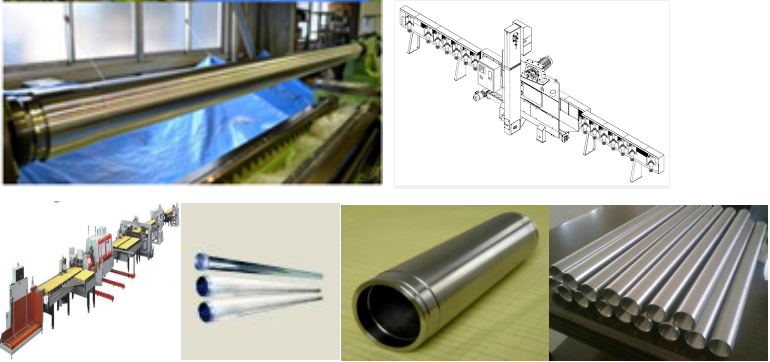

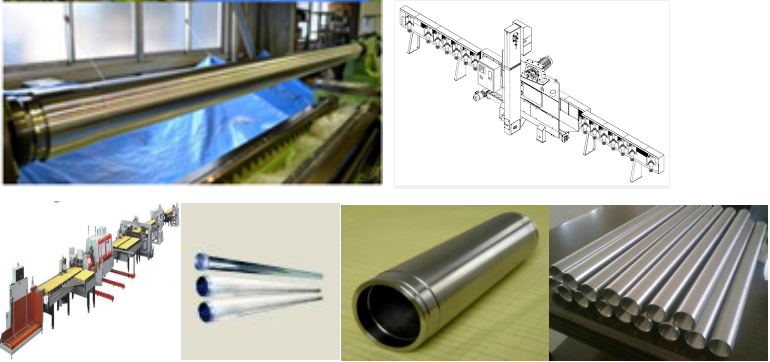

Process flow

Silicon Aluminum Powder & gt; Lined Tube Sandblast & gt; Arc Spray Substrate & gt; Plasma Spray & mdash; & gt; Polishing & Packaging

The main process description:

Silicon aluminum powder: In order to ensure the process stability, the need to purchase silicon ingots, aluminum ingots through the milling, sieving, mixing powder preparation of spraying Si-Al powder.

Sand Blasting Process: The purchased target liner can not be used directly. In order to make the spray coat firm, it is necessary to polish and sandblast the liner.

Primer: Spraying a certain alloy material as a transition layer between the spray coating and the liner, the role is to make the coating and the liner more firmly connected to the base wire made of nickel-aluminum alloy.

Spraying process: This process is the main part of the whole production. The target specifications are different. The spraying time is short. The production capacity of a single spraying equipment is very limited. It can produce a target with the length of 3897mm for more than 30 hours Since the spray gun tip is a consumable, it may be necessary to change the spray gun tip several times during spraying.

Machining process: After the spray process is completed, the surface needs to be processed to meet the specifications required by the user.

Turnkey project special recommendation:(Thermal Spray Equipment Production Line Project)